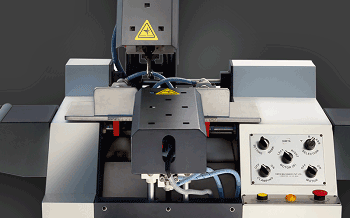

Water Slotting is a very important operation for the construction industry. The machine creates slots in the profile’s drain chamber to take out any water collected through rain or washing. Precision in making drain slots and ensuring the differential sizes of uPVC windows are appropriately drilled is the USP of SIMTA’s Water Slotting Machines.

Drain chambers in profiles are in different positions. Adjusting handles is a facility given to ensure the machines can be adjusted to suit these varied needs.

Cutting and placing the drain slots have standardized measurements to be followed. In SIMTA’s Water slotting machine, the auto-feeding mechanism ensures that the slots are placed and drilled appropriately.

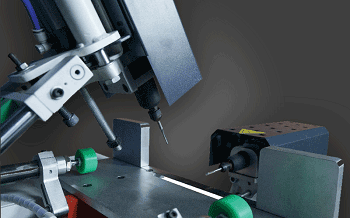

The inner and outer tool mechanisms must function in coordination, and the slots have to be accurately made for their optimal use. SIMTA’s Water slotting machines helps in enabling it through the drain slot multi-tool mechanism.

| Spindle Rotation: | 30000 rpm |

| Max. Profile Height: | 120 mm |

| Max. Profile Width: | 120 mm |

| Input Power: | 1.2 kW |

| Pneumatic Cylinders & Its Accessories: | SMC, Japan. |

| Electrical Components: | Siemens & Schneider Components |

220v, 3 ph, 50-60 Hz.

Up to 6 - Bar

150 kg

H 1200 mm

L 1200 mm

W 700 mm